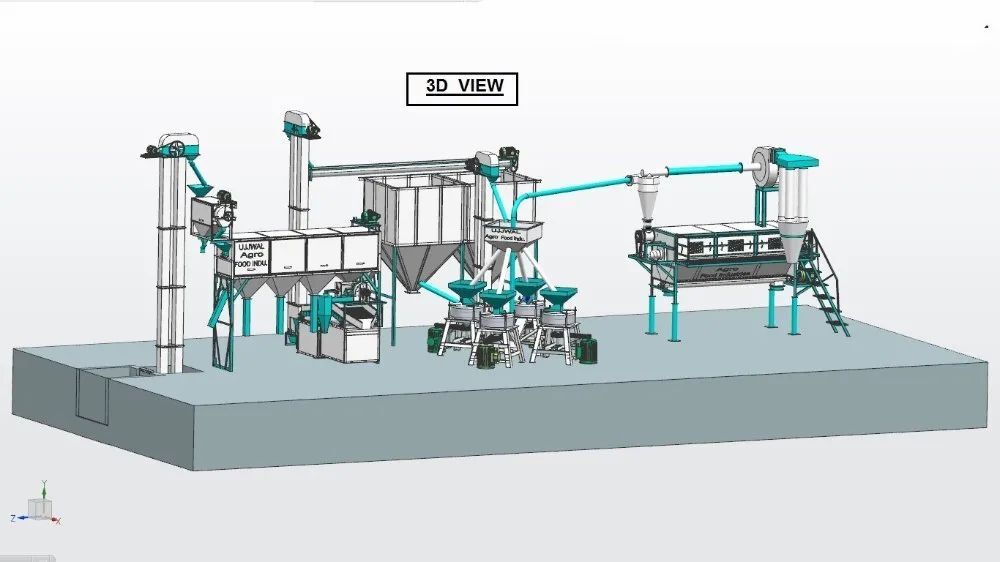

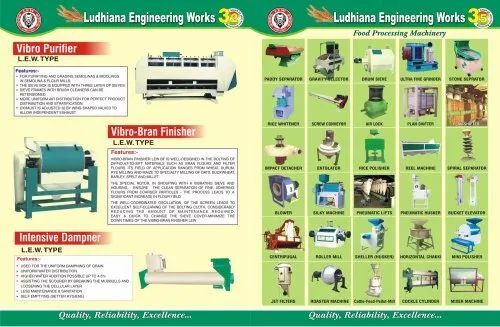

flour mill plant

4500000 INR/Unit

Product Details:

- Product Type machinery

- General Use machinery

- Material Stainless Steel

- Type Flour Grinding Machine

- Capacity requirement based Ton/day

- Weight (kg) requirement based Long Ton

- Computerized Yes

- Click to View more

X

flour mill plant Price And Quantity

- 4500000 INR/Unit

- unit Unit

flour mill plant Product Specifications

- Maize

- Lower Energy Consumption

- Yes

- requirement based Watt (w)

- Roller Mill

- Flour Grinding Machine

- requirement based Long Ton

- requirement based Ton/day

- Manual

- Yes

- Sifter

- Stainless Steel

- 1 year

- requirement based Nanometer (nm)

- machinery

- machinery

flour mill plant Trade Information

- punjab, up

- Cash in Advance (CID)

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- Asia

- All India

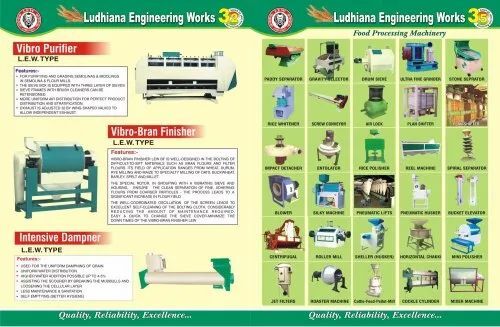

Product Description

We are manufacturing and supplying FLOUR MILL PLANT to various cities including Mumbai, Pune, Bangalore, Jaipur, Kanpur, Lucknow, Noida, Patna, Ranchi, Hyderabad, Imphal, Guwahati, Kolkatta, Assam, Itanagar, Gangtok, Jammu, Kashmir, Srinagar,West Bengal,Varanasi,Meerut,Ghaziabad,Jharkhand,Madhya Pradesh,Prayagraj,Kanpur,Gurgaon,faridabad,Bhiwani,Bhiwandi,Uttarakhand

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email