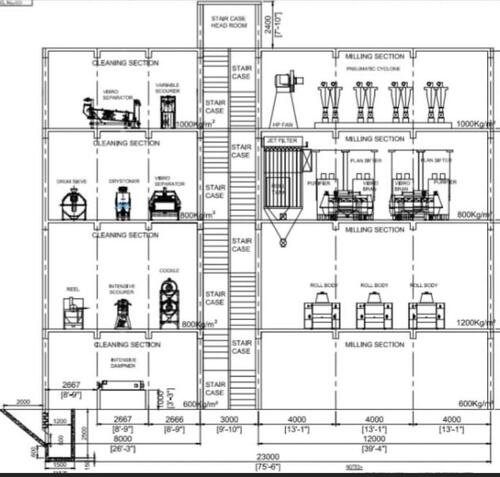

Maida and Suji Making Plant

4500000 INR/Plant

Product Details:

- Product Type Maida and Suji Making Plant

- General Use Maida and Suji Making

- Material Cast Iron

- Type Flour Grinding Machine

- Computerized No

- Automatic Yes

- Control System PLC Control

- Click to View more

X

Maida and Suji Making Plant Price And Quantity

- 1 Plant

- 4500000 INR/Plant

Maida and Suji Making Plant Product Specifications

- No

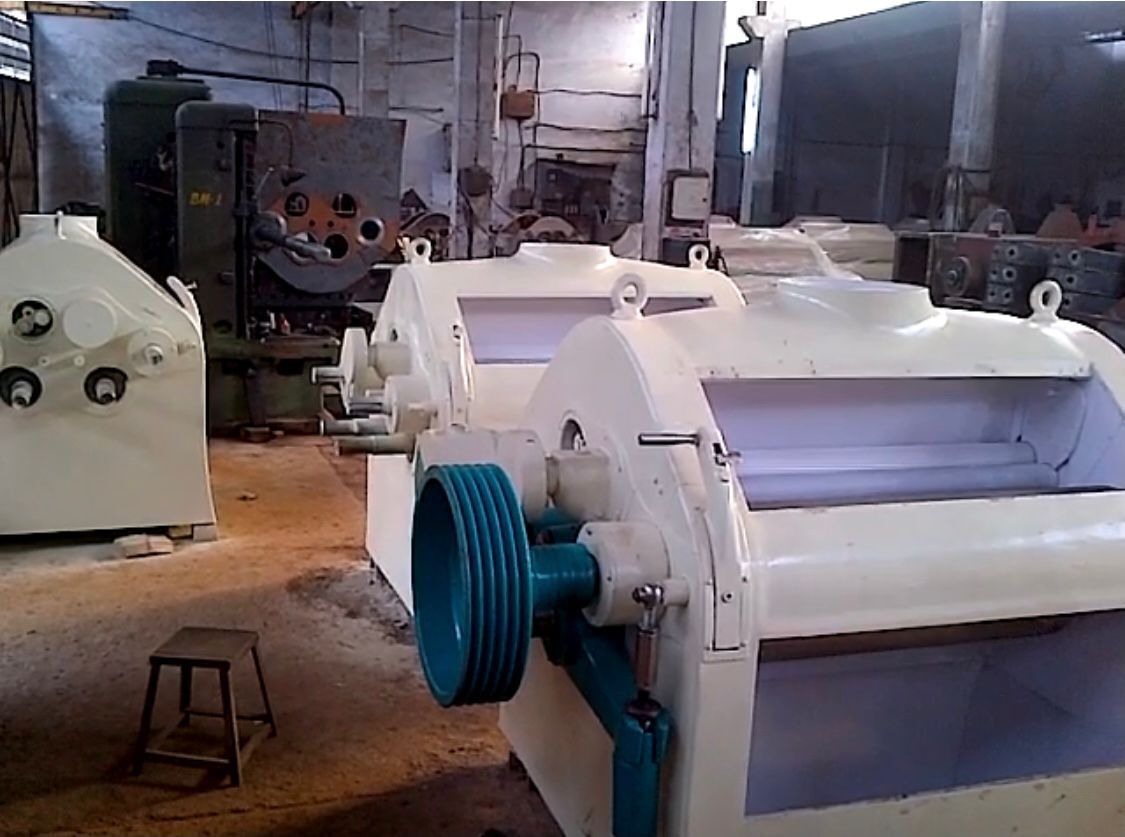

- Roller Mill

- Compact Structure, High Efficiency

- Maida and Suji Making

- Maida and Suji Making Plant

- Flour Grinding Machine

- Wheat

- Yes

- Cast Iron

- PLC Control

Maida and Suji Making Plant Trade Information

- 10 Plant Per Year

- 30-45 Days

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email